100-422222222225 zj Slurry Transfer Transfer Batu Baaran

Rincian Pump ZJ Slurry

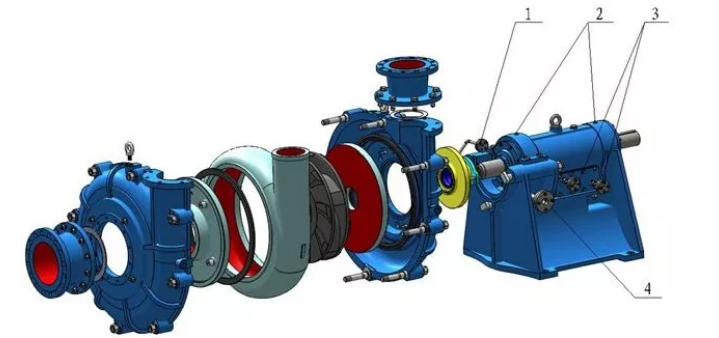

1. Bagean teles kanggo pompa slurry digawe saka aloi utawa karet kromium sing tahan, disesuaikan miturut syarat panuku.

2. Majelis pompa pompa slurry nggunakake struktur silinder, nyetel papan ing antarane impeller lan liner ngarep kanthi gampang. Dheweke bisa dicopot kanthi lengkap nalika didandani. Panganggone MajelisLubrication Grease.

3 .. Segang garan bisa nggunakakePaket Seal, Segel Pakar lan Segel Mekanikal.

4. Cabang sing disusupi bisa dipanggonke ing interval 45 derajat kanthi panjaluk lan orientasi karo wolung posisi sing cocog karo pamondho lan aplikasi.

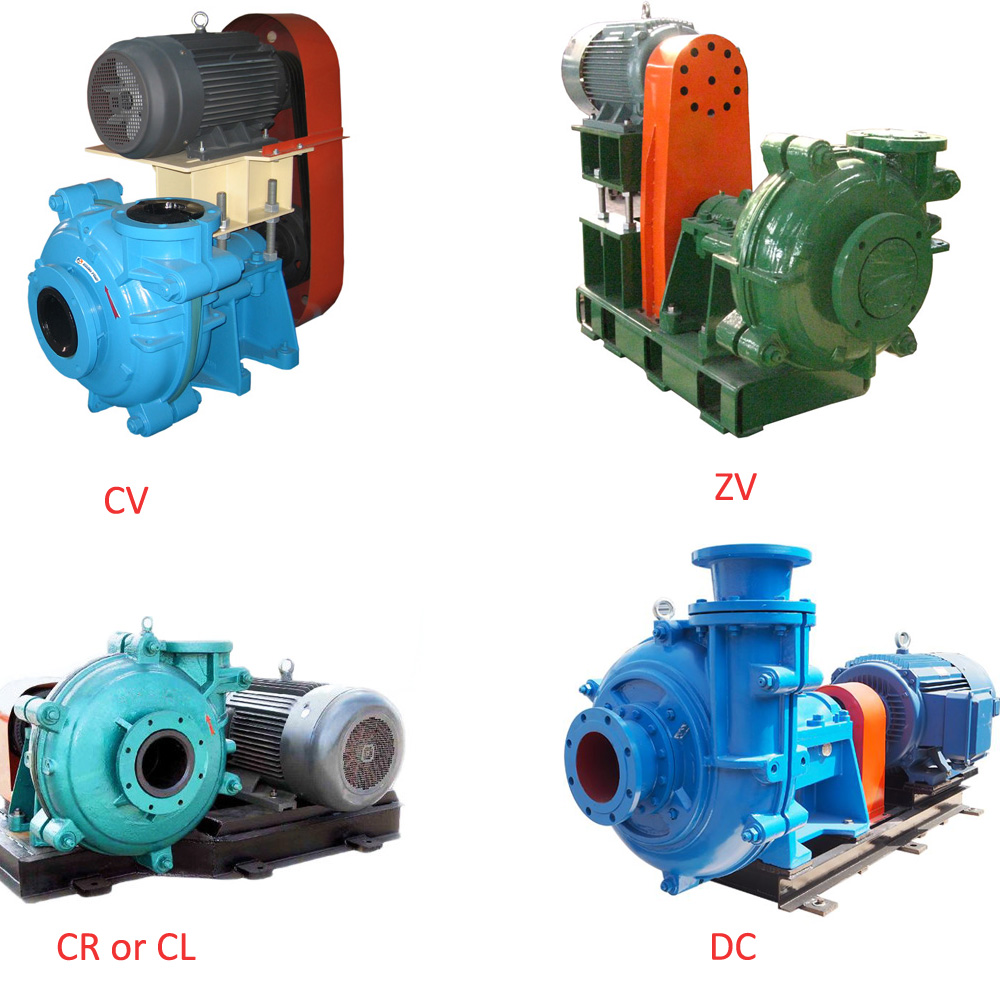

5. Ana jinis drive, kayata Vi Belt drive, Gear Reducer Drive, Golek Cairan Drive, lan Piranti Konversi Frekuensi kanggo Pompa Slurry.

6. Kinerja amba, NPSH NPSH lan efisiensi dhuwur. Pompa slurry bisa diinstal ingSeri Mulstistagekanggo ketemu kiriman kanggo jarak adoh.

Data teknis zj slurry data teknis

| Ukuran | Kapasitas(m3 / h) | Sirah(m) | Max.Daya (KW) | Kacepetan(r / min) | NPSH (m) |

| 40zj | 5.0-20 | 6.0-29 | 4 | 1390-2890 | 2.5 |

| 50zj | 12-39 | 2.6-10.2 | 4 | 940-1440 | |

| 65ZJ | 20-80 | 7.0-33.6 | 15 | 700-1480 | 3 |

| 80zj | 41-260 | 8.4-70.6 | 75 | 700-1480 | 3,5 |

| 100ZJ | 57-360 | 7.7-101.6 | 160 | 700-1480 | 4.1 |

| 150ZJ | 93-600 | 9.1-78.5 | 200 | 500-980 | 3.9 |

| 200ZJ | 215-900 | 215-900 | 355 | 500-980 | 4.4 |

| 250ZJ | 281-1504 | 13.1-110.5 | 800 | 500-980 | 5.3 |

| 300zj | 403-2166 | 10.0-78.0 | 630 | 400-590 | 4.8 |

Aplikasi pompa zj slurry

Pompa bisa digunakake ing pirang-pirang aplikasi, kayata transportasi pipa, pangolahan mineral, pemrosesan batu bara, pangolahan kimia, pangolahan lem, pabrik bahan kimia, operasi kimia, operasi kokain, nangani awu.

Paket Pump Paket ZJ Slurry

Pump slurry utawa bagean pompa slurry bakal dikempalken ing kasus kayu.

Kita bakal nempelake tandha kiriman ing paket miturut syarat panuku.

For more information about our pumps, please send email to: rita@ruitepump.com

TH CANTILILLEVE, Bahan pompa slurry slurry:

| Kode Bahan | Katrangan Bahan | Komponen aplikasi |

| A05 | 23% -30% IIron putih | Impeller, liner, impor, cincin fasilis, kothak stuff, troatbush, plate plate piring |

| A07 | 14% -18% wesi putih putih | Impeller, liner |

| A49 | 27% -29% wesi karbon putih karbon kurang karbon | Impeller, liner |

| A33 | 33% crrosi empung & resistensi corrosion wesi putih | Impeller, liner |

| R55 | Karet Alam | Impeller, liner |

| R33 | Karet Alam | Impeller, liner |

| R26 | Karet Alam | Impeller, liner |

| R08 | Karet Alam | Impeller, liner |

| U01 | Polyurethane | Impeller, liner |

| G01 | Wesi abu-abu | Piring bingkai, piring tutup, pakar, dering fracer, omah |

| D21 | Wesi Ductile | Piring bingkai, piring tutup, omah |

| E05 | Baja karbon | Gagang |

| C21 | Stainless Steel, 4Cr13 | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C22 | Stainless steel, 304ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C23 | Stainless Steel, 316ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| S21 | Karet Butyl | Cincin bareng, segel sendi |

| S01 | Karet epdm | Cincin bareng, segel sendi |

| S10 | Nitrile | Cincin bareng, segel sendi |

| S31 | Hipalon | Impeller, liner, cincin pakar, ahli, dering, sendhi gabungan |

| S44 / K S42 | Neoprene | Impeller, liner, dering bareng, segel sendi |

| S50 | Viton | Cincin bareng, segel sendi |