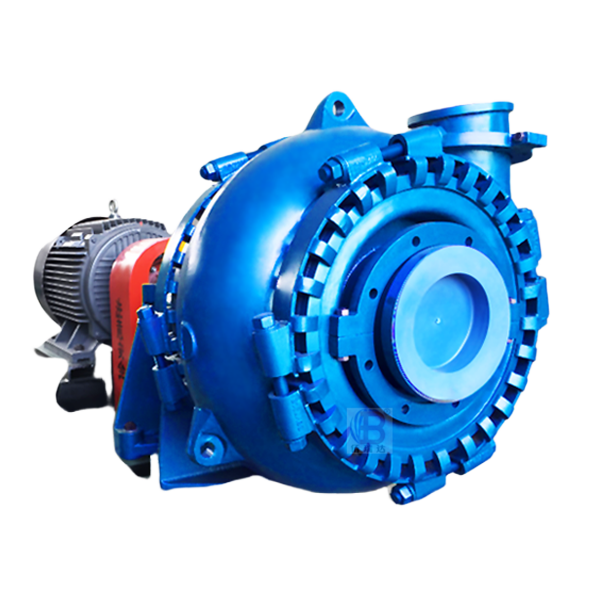

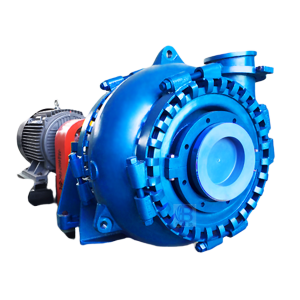

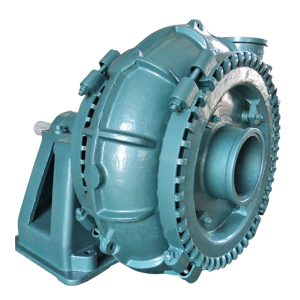

Tg kerikil wedhi wedhi wedhi: perawatan slurry partikel gedhe

Wedhi tg / tghPompa gravelsdirancang khusus kanggo pompa slurries sing agresif banget, menehi, lan sands. kanthi distribusi ukuran partikel. Bisa nangani partikel gedhe kanthi efisiensi kanthi efektif babagan biaya kepemilikan. Profil internal volume gedhe saka casing nyuda kecepatan sing gegandhengan karo urip komponen.

Fitur Desain

Celup clamp segmen unik sing unik ing unit ukuran sing luwih gedhe lan padhet ing pompa sing luwih cilik, nggampangake rotasi casing menyang sudut, nyuda kabutuhan kanthi biaya sing larang regane. Pangopènan minimal dibutuhake.

√ EXPELLER ACHULSION VANANES nyuda tekanan kelenjar lan intrusi saka konsentrasi barang padhet sing dhuwur ing wilayah kelenjar. Efisiensi dipertahankan kanthi minimalake recirculation Side.

Van van sing dirancang khusus lan dibentuk kanthi khusus ngidini nangani partikel gedhe sing luar biasa. Desain casing unik lan nyolong vanes nyegah penyelidikan abrasive gangguan ing pasuryan sealing.

√ Casing sing gedhe lan kuat wis dirancang kanggo nyuda kecepatan internal nyebabake kerugian efisiensi minimal lan nyandhang gesang sing apik. Casing kasebut digawe saka telung komponen kanggo nyuda wektu pangopènan lan biaya sing ana gandhengane karo desain OnePiece. (Kajaba 6/4 dg sing duwe rong komponen)

√ Rusak pelatihan tugas sing lubricated Lubricated Mumplizing Taper Roller dipasang minangka standar. Praokan diameter diameter sing kaku kanthi suda overhang minimalake deflection lan geter ing kabeh syarat njamin operasi gratis masalah. Faktor layanan sing ora biasa bisa ngaktifake Majelis kanggo nggawa kabeh radial lan sumbang.

Majelis "-10" (10 unik sing unik dumadi saka V-Supers, dobel piston dobel lan flingrinth eksternal kanthi lubrinths lubricated standar karo kabeh wompa perang

Tg / tghPompa sandras parameter kinerja

| Model | Max. Power P (kw) | Kapasitas q (m3 / h) | Kepala H (m) | Kacepetan n (r / min) | Eff. η (%) | NPSH (m) | Impller dia. (mm) |

| 6 / 4D-TG | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

| 6 / 4e-tg | 120 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

| 8 / 6e-tg | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 391 |

| 10 / 8s-TG | 560 | 216-936 | 852 | 500-1000 | 65 | 3-7.5 | 533 |

| 10 / 8s-tGH | 560 | 180-1440 | 24-80 | 500-950 | 72 | 2.5-5 | 711 |

| 10 / 8f-tg | 260 | 216-936 | 852 | 400-800 | 65 | 3-7.5 | 533 |

| 12 / 10f-tg | 260 | 360-1440 | 1060 | 350-700 | 65 | 1.5-4.5 | 667 |

| 12 / 10g-tg | 600 | 360-1440 | 1060 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12 / 10g-tgh | 600 | 288-2808 | 16-80 | 350-700 | 73 | 2-10 | 950 |

| 14 / 12g-tg | 600 | 576-3024 | 8770 | 300-700 | 68 | 2-8 | 864 |

| 14 / 12t-tg | 1200 | 576-3024 | 8770 | 300-700 | 68 | 2-8 | 864 |

| 16 / 14g-tg | 600 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 1016 |

| 16 / 14t-tg | 1200 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 1016 |

| 16 / 14TU-TGH | 1200 | 324-3600 | 2670 | 300-500 | 72 | 3-6 | 1270 |

| 18 / 16TU-TG | 1200 | 720-4320 | 12-48 | 250-500 | 72 | 3-6 | 1067 |

TG / TGH pasir pasir pumps aplikasi

Tg / TGH Pompa-desain tugas & gravel abot sing bisa digunakake kanggo tugas volume dhuwur, gravels, ngempet, tanduran siklus, pipa pipa, pipa pipa sing luwih dhuwur utawa industri liyane.

Cathetan:

Pompa lan spares lan spares mung diowahi karo WARMAN®G keriting pompa lan spares.

TH CANTILILLEVE, Bahan pompa slurry slurry:

| Kode Bahan | Katrangan Bahan | Komponen aplikasi |

| A05 | 23% -30% IIron putih | Impeller, liner, impor, cincin fasilis, kothak stuff, troatbush, plate plate piring |

| A07 | 14% -18% wesi putih putih | Impeller, liner |

| A49 | 27% -29% wesi karbon putih karbon kurang karbon | Impeller, liner |

| A33 | 33% crrosi empung & resistensi corrosion wesi putih | Impeller, liner |

| R55 | Karet Alam | Impeller, liner |

| R33 | Karet Alam | Impeller, liner |

| R26 | Karet Alam | Impeller, liner |

| R08 | Karet Alam | Impeller, liner |

| U01 | Polyurethane | Impeller, liner |

| G01 | Wesi abu-abu | Piring bingkai, piring tutup, pakar, dering fracer, omah |

| D21 | Wesi Ductile | Piring bingkai, piring tutup, omah |

| E05 | Baja karbon | Gagang |

| C21 | Stainless Steel, 4Cr13 | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C22 | Stainless steel, 304ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C23 | Stainless Steel, 316ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| S21 | Karet Butyl | Cincin bareng, segel sendi |

| S01 | Karet epdm | Cincin bareng, segel sendi |

| S10 | Nitrile | Cincin bareng, segel sendi |

| S31 | Hipalon | Impeller, liner, cincin pakar, ahli, dering, sendhi gabungan |

| S44 / K S42 | Neoprene | Impeller, liner, dering bareng, segel sendi |

| S50 | Viton | Cincin bareng, segel sendi |