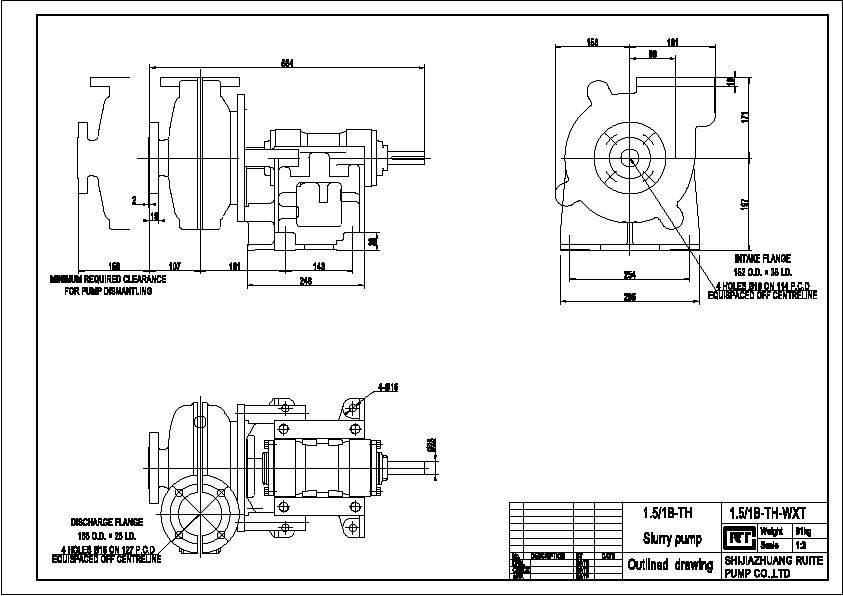

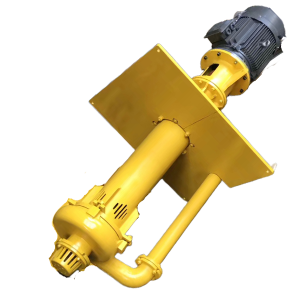

Pump 1,5 / 1c-HH Slurry Pump Slurry Pump

Katrangan

1.5 / 1c-ThhPompa slurry sirah dhuwurdirancang kanggo ngasilake kepala ing tahap dhuwur ing tekanan sing dhuwur, umume digunakake kanggo slurries transportasi jarak jauh, tembaga, lan liya-liyane digunakake kanggo ngeterake pompa, tentara, lan sapiturute 1.c, lan sapiturute 1.c, lan sapiturute 1.c, lan sapiturute 1.c, lan sapiturute 1.c, lan sapiturute 1.c. 1.:. Pumps slurry thh seri.

1,5 / 1 C-ThhHigh Slurry Pompa Pagelaran Slurry:

| Model | Max. Kekuwatan(kw) | Bahan | Kinerja banyu sing jelas | ImpellerVane Nomer | |||||

| Liner | Impeller | Kapasitas q(m3 / h) | Kepala H(m) | Kacepetan n(rpm) | Eff. η(%) | NPSH(m) | |||

| 1.5 / 1c-thh | 30 | M | M | 16.2 ~ 34.2 | 29 ~ 92 | 1400 ~ 2200 | 20 | 2 ~ 5.5 | 5 |

1,5 / 1 C-ThhTinggi Gesang Slurry Pump Aplikasi:

Pompa slurry sentrifugal sing dhuwur banget kanggo nggunakake pangiriman tailings, pangolahan mineral, prep bara, lambe, lambe, botol, besar minyak, buntut, asam fly, asifas, asam fly, lsp

Fitur

1. Struktur cylindrical saka Majelis Bearing: Trep kanggo nyetel papan ing antarane impeller lan liner ngarep lan bisa dicopot kanthi lengkap;

2. Bagean teles anti-abrasi:Bagéan teles bisa digawe saka karet cetakan tekanan. Dheweke rampung bisa diowahi kanthi bagean teles logam.

3 .. cabang sing disusupi bisa orientasi saka wolung posisi ing interval 45 derajat;

4. Macem-macem jinis drive: DC (sambungan langsung), drive v-belt, kothak gear, kentang vfd, kendali hidrik, lsp;

5. Segel Ahaft nggunakake segel ngemas, segel pakar lan segel mekanik;

Rincian liyane

TH CANTILILLEVE, Bahan pompa slurry slurry:

| Kode Bahan | Katrangan Bahan | Komponen aplikasi |

| A05 | 23% -30% IIron putih | Impeller, liner, impor, cincin fasilis, kothak stuff, troatbush, plate plate piring |

| A07 | 14% -18% wesi putih putih | Impeller, liner |

| A49 | 27% -29% wesi karbon putih karbon kurang karbon | Impeller, liner |

| A33 | 33% crrosi empung & resistensi corrosion wesi putih | Impeller, liner |

| R55 | Karet Alam | Impeller, liner |

| R33 | Karet Alam | Impeller, liner |

| R26 | Karet Alam | Impeller, liner |

| R08 | Karet Alam | Impeller, liner |

| U01 | Polyurethane | Impeller, liner |

| G01 | Wesi abu-abu | Piring bingkai, piring tutup, pakar, dering fracer, omah |

| D21 | Wesi Ductile | Piring bingkai, piring tutup, omah |

| E05 | Baja karbon | Gagang |

| C21 | Stainless Steel, 4Cr13 | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C22 | Stainless steel, 304ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C23 | Stainless Steel, 316ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| S21 | Karet Butyl | Cincin bareng, segel sendi |

| S01 | Karet epdm | Cincin bareng, segel sendi |

| S10 | Nitrile | Cincin bareng, segel sendi |

| S31 | Hipalon | Impeller, liner, cincin pakar, ahli, dering, sendhi gabungan |

| S44 / K S42 | Neoprene | Impeller, liner, dering bareng, segel sendi |

| S50 | Viton | Cincin bareng, segel sendi |