Pump Tinggi Pump Hobi China Pump Sand Pump Pump pump lima sludge pump sludge pompa pump emas pertambangan pompa

Biasane orientasi pelanggan, lan dadi fokus utama kanggo ora mung salah sawijining panyedhiya sing tanggung jawab, sing dipercaya lan jujur, nanging uga mitra sing bisa dipasangi Sand Pompa Pump Slurry pump Kasetyan lan komitmen kita tetep kanthi hormat ing dhukungan sampeyan. Nelpon dina iki kanggo informasi luwih lengkap, tahan saiki.

Biasane orientasi pelanggan, lan dadi fokus utama kanggo ora mung salah sawijining panyedhiya sing tanggung jawab, sing dipercaya lan jujur, nanging uga mitra kanggo klien kitaChina Pump and Slurry Pump, Kanthi mantep karo patronase sampeyan lan bakal ngladeni para klien ing omah lan ing luar negeri karo barang-barang sing luwih apik lan layanan sing apik banget kanggo tren pangembangan luwih akeh kaya biasane. Kita pracaya sampeyan bakal entuk manfaat saka profesionalisme kanthi cepet.

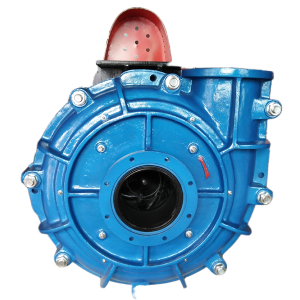

Pompa slurus thr dadi pompa slurrypadha karo ah Metam sing diantrekake pompa slurry ing struktur. Bentenane utama ing antarane AH lan thr minangka bahan saka biji, yaiku karet alami, karet sintetis utawa karet sintetik liyane. Pompa lemes sing diantrekake thi-karet luwih cocog kanggo ngirim slurries sing kuwat utawa abrasive ukuran ukuran tanpa sudhut sing cetha.

Fitur Desain:

√ Konstruksi tugas abot kanthi desain liwat-bolt nyedhiyakake gampang pangopènan lan downtime minimal.

√ Iron Ductile Lengkap Casing menehi daya tahan, kekuatan, safety, lan urip layanan sing dawa.

√ diameter gedhe, ngowahi alon-alon, impler efisiensi dhuwur sing dirancang kanggo nggayuh gaya sing maksimal lan biaya operasi sing sithik.

√ Gedhe, bukak periut internal sing dirancang kanggo nyuda kecepatan internal, maksimal nyandhang urip lan biaya operasi sing luwih murah.

Man lineers line-line-line-lensa utawa alloy sacara kandel nyedhiyakake resistensi karat sing unggul ditambah yaiku nawakake gampang liner ganti lan selaras kanggo nyuda biaya pangopènan sakabehe lan maksimal nyandhang gesang.

√ Minimal shaft / impeller overhang nyuda gagang batang lan nambah umur kemasan.

Majelis Bearing Gaya Cartridge ngidini kanggo pangopènan ing lingkungan sing resik tanpa mbusak pompa slurry, nyebabake operasi sing bisa dipercaya lan urip sing luwih dawa.

√ Opsi pengawas utawa lenga lubricelly Opsi sing bakal dadi gampang pangopènan lan suda Downtime.

√ segel gael garing sing diurutake utawa ngilangi syarat banyu siram.

√ Pengobatan sing efektif berpanjian umur nalika nyuda utawa ngilangi syarat banyu siram.

√ Penyusunan segel - siram lengkap, aliran rendah, sentrifugal, utawa segel mekanik bisa dipasang ing pompa slurry sing ukurane.

Paramèter kinerja kinerja pompa

| Model | Max. Kekuwatan (kw) | Bahan | Kinerja banyu sing jelas | Impeller Vane Nomer | |||||

| Liner | Impeller | Kapasitas q (m3 / h) | Kepala H (m) | Kacepetan n (rpm) | Eff. η (%) | NPSH (m) | |||

| 1,5 / 1b-thr | 15 | Karet | Karet | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 2-4 | 3 |

| 2 / 1.5b-thr | 15 | Karet | Karet | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 3.5-8 | 5 |

| 3 / 2c-thr | 30 | Karet | Karet | 36-75.6 | 13-39 | 1300-2100 | 55 | 2-4 | 5 |

| 4 / 3c-thr | 30 | Karet | Karet | 79.2-180 | 5-34.5 | 800-1800 | 59 | 35 | 5 |

| 4 / 3D-thr | 60 | Karet | Karet | 79.2-180 | 5-34.5 | 800-1800 | 59 | 35 | 5 |

| 6 / 4d-thr | 60 | Karet | Karet | 144-324 | 12-45 | 800-1350 | 65 | 35 | 5 |

| 6 / 4e-thr | 120 | Karet | Karet | 144-324 | 12-45 | 800-1350 | 65 | 35 | 5 |

| 8 / 6e-thr | 120 | Karet | Karet | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | 5 |

| 8 / 6r-thr | 300 | Karet | Karet | 324-720 | 7-49 | 400-1000 | 65 | 5-10 | 5 |

| 10 / 8st-thr | 560 | Karet | Karet | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | 5 |

| 10 / 8e-m | 120 | Karet | Karet | 540-1188 | 10-42 | 500-900 | 79 | 5-9 | 5 |

| 12 / 10st-thr | 560 | Karet | Karet | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | 5 |

| 14/7st-thr | 560 | Karet | Karet | 1152-2520 | 13-44 | 300-500 | 79 | 38 | 5 |

| 16 / 14st-thr | 560 | Karet | Karet | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 5 |

| 18 / 16TU-thr | 1200 | Karet | Karet | 2160-5040 | 8-66 | 200-500 | 80 | 4.5-9 | 5 |

| 20 / 18TU-thr | 1200 | Karet | Karet | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 |

Aplikasi Pompa Karet Diantrih:

Series thr karet pompa slurry digunakake akeh digunakake ing pangolahan mineral, bocor, cinta, media minyak, flosp, material, media fosforic, bahan kimia fosfop, pulp lan Kertas, Rod Mill Discharge, Pabrik Pabrik, Crushers Wet etc.

* Pompa slurus sing diantrekake lan laras mung bisa diowahi karo WARMAN®Pompa slurus sing diantemi Thr

Biasane orientasi pelanggan, lan dadi fokus utama kanggo ora mung salah sawijining panyedhiya sing tanggung jawab, sing dipercaya lan jujur, nanging uga mitra sing bisa dipasangi Sand Pompa Pump Slurry pump Kasetyan lan komitmen kita tetep kanthi hormat ing dhukungan sampeyan. Nelpon dina iki kanggo informasi luwih lengkap, tahan saiki.

Pemasok CinaChina Pump and Slurry Pump, Kanthi mantep karo patronase sampeyan lan bakal ngladeni para klien ing omah lan ing luar negeri karo barang-barang sing luwih apik lan layanan sing apik banget kanggo tren pangembangan luwih akeh kaya biasane. Kita pracaya sampeyan bakal entuk manfaat saka profesionalisme kanthi cepet.

TH CANTILILLEVE, Bahan pompa slurry slurry:

| Kode Bahan | Katrangan Bahan | Komponen aplikasi |

| A05 | 23% -30% IIron putih | Impeller, liner, impor, cincin fasilis, kothak stuff, troatbush, plate plate piring |

| A07 | 14% -18% wesi putih putih | Impeller, liner |

| A49 | 27% -29% wesi karbon putih karbon kurang karbon | Impeller, liner |

| A33 | 33% crrosi empung & resistensi corrosion wesi putih | Impeller, liner |

| R55 | Karet Alam | Impeller, liner |

| R33 | Karet Alam | Impeller, liner |

| R26 | Karet Alam | Impeller, liner |

| R08 | Karet Alam | Impeller, liner |

| U01 | Polyurethane | Impeller, liner |

| G01 | Wesi abu-abu | Piring bingkai, piring tutup, pakar, dering fracer, omah |

| D21 | Wesi Ductile | Piring bingkai, piring tutup, omah |

| E05 | Baja karbon | Gagang |

| C21 | Stainless Steel, 4Cr13 | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C22 | Stainless steel, 304ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C23 | Stainless Steel, 316ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| S21 | Karet Butyl | Cincin bareng, segel sendi |

| S01 | Karet epdm | Cincin bareng, segel sendi |

| S10 | Nitrile | Cincin bareng, segel sendi |

| S31 | Hipalon | Impeller, liner, cincin pakar, ahli, dering, sendhi gabungan |

| S44 / K S42 | Neoprene | Impeller, liner, dering bareng, segel sendi |

| S50 | Viton | Cincin bareng, segel sendi |