Pompa desultifurasi ing tanduran tenaga kerja

Pump Dt Series FGD gypsum pompaApa tahap tunggal, Pompa sentrifugal tunggal horisontal. Digunakake utamane minangka pompa ing menara penyerap ing sistem FGD. Nduwe kaluwihan kapasitas sawetara, efisiensi dhuwur, energi sing teles dlock, bagean sing teles dirancang karo teknologi analisis cairan cfd kanggo njamin operasi efisiensi dhuwur. Pompa slurry DT FGD minangka jinis pompa optimal kanggo ngangkut slurry gypsum, slurry gamping utawa medium abrasive lan corrosive liyane ing tanduran tenaga termals.

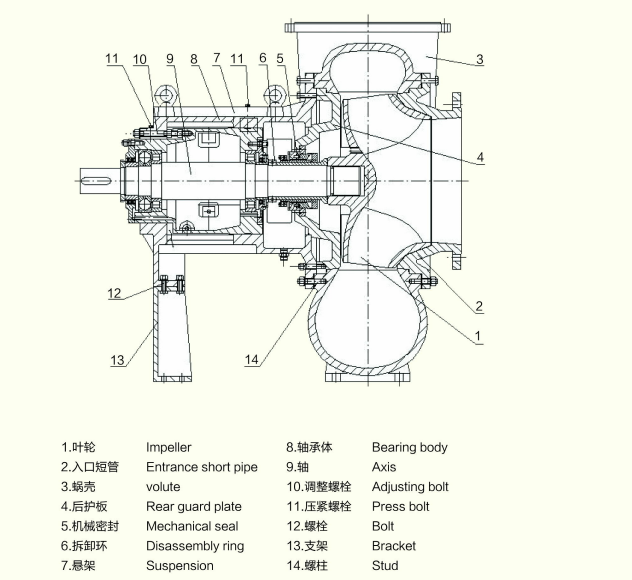

- Struktur Pump Pump Dt Series Desulfurization

- Data kinerja Pump Dt Desulfurization

| Model | Max Powerkw | KapasismeMM3 / H | Headm | SPEEDR / min | NPSHM | Maxparicle sing diidini mm | Pompa weightkg |

| 800dt-A90 | 900 | 3142-9700 | 6-28.7 | 300-592 | 2 | 181 | 5900 |

| 700dt-A84 | 630 | 2157-7360 | 5.2-24.5 | 300-591 | 2 | 168 | 5420 |

| 600DT-A82 | 500 | 1664-5600 | 5.2-27.8 | 300-595 | 2.2 | 152 | 4900 |

| 500Dt-A85 | 400 | 1036-4080 | 5.7-26.8 | 300-591 | 3.1 | 135 | 4500 |

| 350dt-A78 | 500 | 720-2865 | 11.6-51.1 | 400-740 | 3,5 | 104 | 3700 |

| 300Dt-A60 | 400 | 580-2403 | 8.9-53.1 | 490-989 | 4.3 | 96 | 2790 |

| 200dt-B45 | 90 | 138-645 | 5.7-31.0 | 490-990 | 2 | 51 | 1750 |

| 100dt-A50 | 90 | 62-279 | 9.3-44.6 | 490-980 | 2.1 | 30 | 1470 |

| 100dt-A35 | 75 | 77-323 | 8.8-45.9 | 700-1480 | 1.9 | 42 | 550 |

| 65dt-A40 | 55 | 34-159 | 12.2-63.2 | 700-1480 | 2.1 | 16 | 490 |

| 50DT-A30 | 18.5 | 16-78 | 6.1-36.3 | 700-1460 | 0,8 | 16 | 210 |

- Pompa dt desulfurizationFitur

Efisiensi dhuwur, ngirit energi, nyandhang nolak, anti-corrosive, swara lan geter,

Tes operasi operasi sing stabil

Wektu layanan dawa sing trep kanggo ndandani

- Contone aplikasi aplikasi Pump Dt Desulfurization

Digunakake kanthi umum ing generasi daya termal, sistem desulfurization industri nyaring transporting gamping utawa slurry gypsum.

- Paket Pump Desulfurization lan Pengiriman

Kanggo informasi luwih lengkap babagan pompa desulfurasi, hubungi kita kanthi bebas.

Email: rita@ruitepump.com

Samsung / WeChat: +8619933139867

TH CANTILILLEVE, Bahan pompa slurry slurry:

| Kode Bahan | Katrangan Bahan | Komponen aplikasi |

| A05 | 23% -30% IIron putih | Impeller, liner, impor, cincin fasilis, kothak stuff, troatbush, plate plate piring |

| A07 | 14% -18% wesi putih putih | Impeller, liner |

| A49 | 27% -29% wesi karbon putih karbon kurang karbon | Impeller, liner |

| A33 | 33% crrosi empung & resistensi corrosion wesi putih | Impeller, liner |

| R55 | Karet Alam | Impeller, liner |

| R33 | Karet Alam | Impeller, liner |

| R26 | Karet Alam | Impeller, liner |

| R08 | Karet Alam | Impeller, liner |

| U01 | Polyurethane | Impeller, liner |

| G01 | Wesi abu-abu | Piring bingkai, piring tutup, pakar, dering fracer, omah |

| D21 | Wesi Ductile | Piring bingkai, piring tutup, omah |

| E05 | Baja karbon | Gagang |

| C21 | Stainless Steel, 4Cr13 | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C22 | Stainless steel, 304ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| C23 | Stainless Steel, 316ss | Lengan Shaft, Lantern Ring, Watesan Lantern, Cincin Neck, Gland Gland |

| S21 | Karet Butyl | Cincin bareng, segel sendi |

| S01 | Karet epdm | Cincin bareng, segel sendi |

| S10 | Nitrile | Cincin bareng, segel sendi |

| S31 | Hipalon | Impeller, liner, cincin pakar, ahli, dering, sendhi gabungan |

| S44 / K S42 | Neoprene | Impeller, liner, dering bareng, segel sendi |

| S50 | Viton | Cincin bareng, segel sendi |